Products Detalis

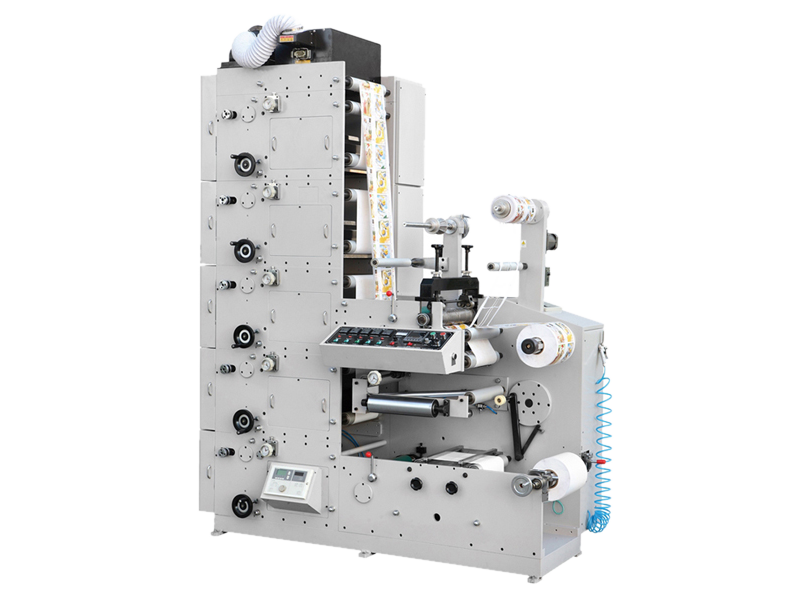

RY-320 Flexo Printing Machine

- Categories: Flexo Printing Machine

- E-mail:info@lin-tek.com

- TEL:+86-15869682150

- Skype:lint1987

- Whatsapp:+86-15869682150

- Share:

Standard Configuration:

1.One mounting machine

2.One anilox roller for each group

3.Three sets printing rollers (3*5=15)

4.Printing both sides at the same time (with turn bar)

5.With the lamination station

6.One unwinding tension controller

7.One rewinding tension controller

8.One rotary die cutting station

Characteristics:

1. Adopt the anilox roller to spread ink.

2. Unwinding and rewinding are controlled by magnetism power brake, clutch. (or by automatic tension controller of mitsubishi , made in Japan).

3. Printing unit adopt 360º for registration.

4. Printing unit have one infrared to dry the device group each.

5. The rubber roller can break away from automatically while parking, and running at a low speed, in order to avoid water being black to be dry.

6. The main motor is adopted the import stepless regulation of frequency conversion.

7. Unwinding, printing, varnishing, IR drying, laminating and rewinding can be finished in one process, this kind of printing machine is best for each printing companies to print on adhesive-paper labels and other commercial label.

Main technical parameter:

|

Model |

RY320 |

|

Printing speed |

60m/min |

|

Printing color |

1-6colors |

|

Max. Web width |

320mm |

|

Max. Printing width |

310mm |

|

Max. Unwinding diameter |

600mm |

|

Max. Rewinding diameter |

550mm |

|

Printing girth |

175-320mm |

|

Precision of registration |

±0.10mm |

|

Dimensions |

2100*1100*2500(mm) |

|

Machine weight |

About 2200kg |