Products Detalis

Automatic Face Mask Making Machine

- Categories: Face Mask Making Machine

- E-mail:info@lin-tek.com

- TEL:+86-15869682150

- Skype:lint1987

- Whatsapp:+86-15869682150

- Share:

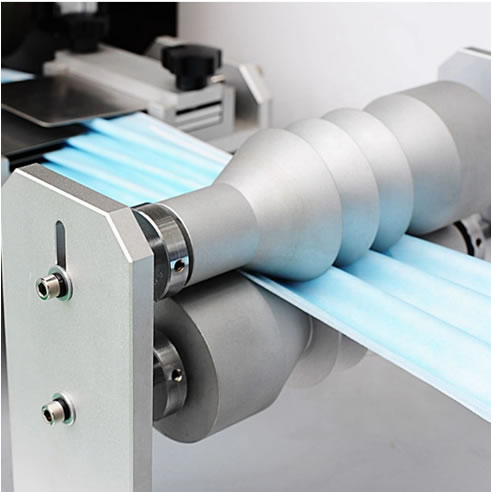

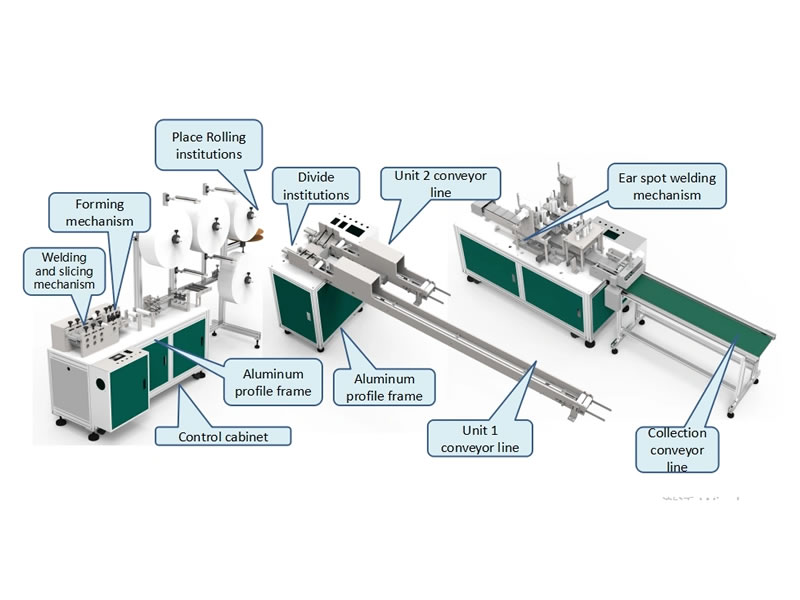

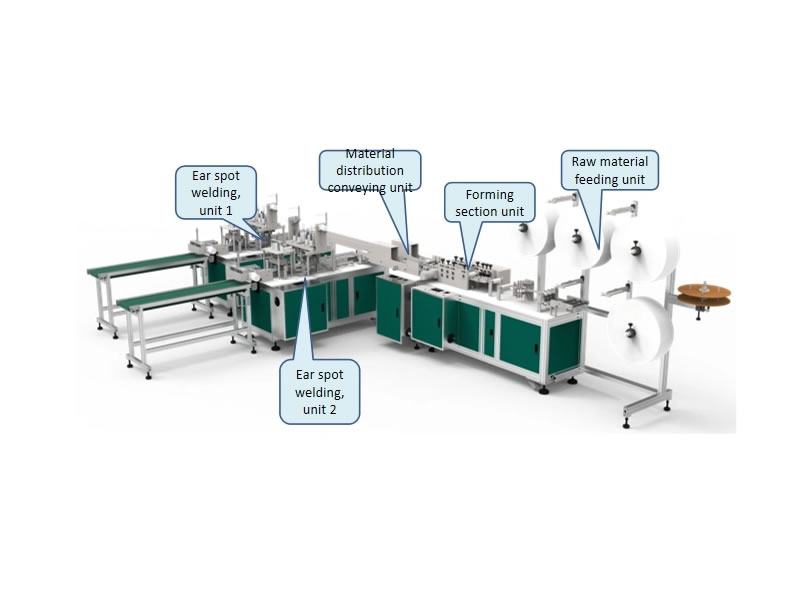

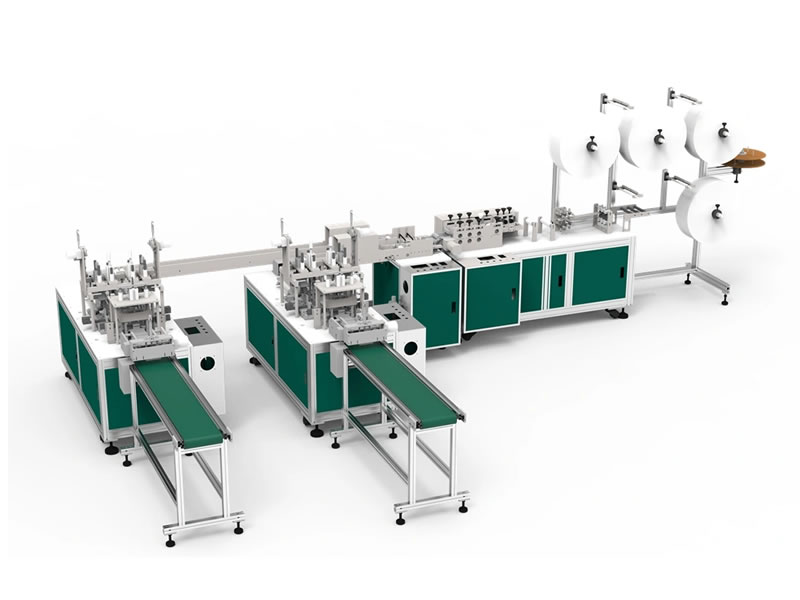

This automatic face mask making machine is mainly used for the automatic forming of flat masks: the whole roll of fabric is driven by rollers after unwinding, and the fabric is automatically folded and hemmed; the entire length of the bridge is pulled and unrolled. Ultrasonic welding to the seal, then ultrasonic side sealing, cutting and shaping with a cutter; conveying the mask to the two mask earband welding stations through an assembly line, and finally forming the mask by ultrasonic welding; when the mask is made, The pipeline is transported to the flat belt line for collection.

Equipment process:

Mask machine slicing: unwinding-ultrasonic compound-nasal bridge insertion-precompression compound-folding view-precompression compound-ultrasonic Compound-rolling

Mask connection line: the connection device that automatically transfers the manufactured body mask to the conveyor line of the mask ear band machine Mask connection line: the connection device that automatically transfers the manufactured body mask to the conveyor line of the mask ear band machine

Mask outer ear strap machine: Feed into the body ,Cut tape for size , Raw materials required for ultrasonic welding

Non-woven outer layer (175MM, weight about 25G), PP non-woven composite fiber;

The middle layer is a meltblown cloth (170-200MM, the weight is about 25G);

Non-woven inner layer (190-200MM, weight 25G), PP non-woven composite fiber;

Nose bridge silk plastic strip PP 5.0MM * 0.55MM;

Ear band is round with a diameter of 2.5-3MM;

Main Technical Parameter:

|

Product Name |

Automatic Face Mask Machine |

|

Applicable mask type |

General medical mask Surgical mask |

|

Applicable materials |

PP non-woven fabric, synthetic fiber |

|

Speed |

100pcs/min (140,000pcs per day) |

|

Qualification Rate |

98-99%(except when the incoming materials do not meet the requirements or employees' improper operation is excluded) |

|

Equipment failure rate |

≤2% |

|

Mask Size |

175mm*95mm |

|

Processing methods |

Ultrasonic welding |

|

Operation screen |

10 inch |

|

Control system |

PLC |

|

Number of applicable layers |

3 layers |

|

Voltage |

220VAC 50HZ |

|

Pressure |

0.6Mpa |

|

Power |

≤10KW |

|

Dimension |

6500x3500x1950mm |

|

Feature |

High stability, Two output line , high capacity |

|

HS Code |

847780000 |